TRIVETTE HISTORICAL PICTURES

-- 1974 --

It was February 20th 1974 when the first article appeared in the Ventura Starview press showing the scale model of the vehicle. On March

11th 1974 Transportation content company (a limited partnership) was formed, with 10 investors at $1,000 each.

It was February 20th 1974 when the first article appeared in the Ventura Starview press showing the scale model of the vehicle. On March

11th 1974 Transportation content company (a limited partnership) was formed, with 10 investors at $1,000 each.

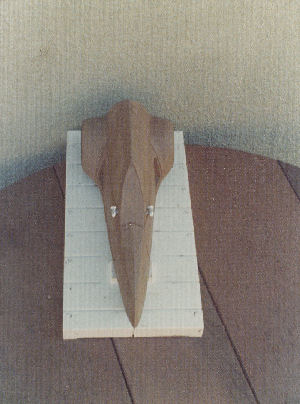

This is a picture of the scale model. The rear view mirrors are from a plastic kit of another car.

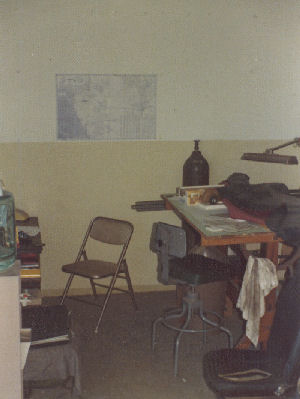

This is the shop on 1330 Callins road where the work of designing and building the prototype began. This shows a picture of Bob's

drafting table and desk. If you look closely you can see the scale model of the car. This is the drafting table that all of Bob's

vehicles were designed on and he continues to design on today.

This is the shop on 1330 Callins road where the work of designing and building the prototype began. This shows a picture of Bob's

drafting table and desk. If you look closely you can see the scale model of the car. This is the drafting table that all of Bob's

vehicles were designed on and he continues to design on today.

One of the work tables used in the shop. This picture was taken around June of 1974.

One of the work tables used in the shop. This picture was taken around June of 1974.

Another picture of the shop complete with "welder boy" as Bob was known then. You can see some of the TriVette parts, tires etc.,

laying around.

Another picture of the shop complete with "welder boy" as Bob was known then. You can see some of the TriVette parts, tires etc.,

laying around.

Welder Boy welding the frame of the prototype using a MIG welder. He still has and uses that welder. The frame here is upside down

and you can tell it's the prototype because it's the only one that square tubing was used on. All of the production cars used

round tubing.

Welder Boy welding the frame of the prototype using a MIG welder. He still has and uses that welder. The frame here is upside down

and you can tell it's the prototype because it's the only one that square tubing was used on. All of the production cars used

round tubing.

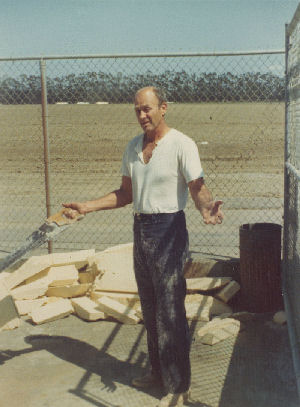

This is the full size plywood form before it was sent to the "foaming" shop.

This is the full size plywood form before it was sent to the "foaming" shop.

The wood form was taken to a place in Oxnard California to be foamed. Where they made large planters for malls and such. The foam was

actually used on the outside of the planters etc. for shipping protection. The plywood mockup was then sprayed by them and it's shown

here at the shops side yard. Behind this is the motorhome chasis that Bob was working on for American motors.

The wood form was taken to a place in Oxnard California to be foamed. Where they made large planters for malls and such. The foam was

actually used on the outside of the planters etc. for shipping protection. The plywood mockup was then sprayed by them and it's shown

here at the shops side yard. Behind this is the motorhome chasis that Bob was working on for American motors.

One of the partners, Dick Downey, helping cut off surplus foam using 2 adjacent plywood stations to guide the handsaw. This created

a segmented surface. Drywall compound was then used to smooth this surface.

One of the partners, Dick Downey, helping cut off surplus foam using 2 adjacent plywood stations to guide the handsaw. This created

a segmented surface. Drywall compound was then used to smooth this surface.

The unit was taken to the Ventura Marina where they applied fiberglass to the outside of the "plug".

The unit was taken to the Ventura Marina where they applied fiberglass to the outside of the "plug".

The plug was brought back to the shop and here they are "finishing" smoothing the surface of the fiberglass.

The plug was brought back to the shop and here they are "finishing" smoothing the surface of the fiberglass.

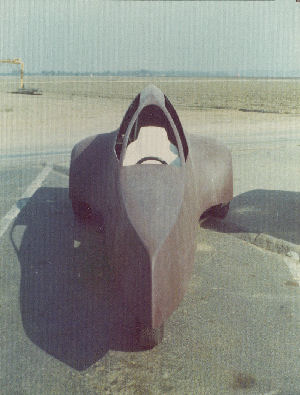

This shows the first fiberglass body for the prototype. At this point it has no headlights, taillights, doors, or returns around

the windows or the winshield. It is just the empty body form. To test the body design Bob and his son sat this body on top of the

chassis and Bob drove the car with one hand and his other hand held up the body. His son held the body up from the rear seat using

both hands. They then drove down the Freeway to insure it was generating downforce!!!! At 55 MPH it generated so much downforce

that Bob couldn't hold it up anymore. It was then decided that that was sufficient downforce.

This shows the first fiberglass body for the prototype. At this point it has no headlights, taillights, doors, or returns around

the windows or the winshield. It is just the empty body form. To test the body design Bob and his son sat this body on top of the

chassis and Bob drove the car with one hand and his other hand held up the body. His son held the body up from the rear seat using

both hands. They then drove down the Freeway to insure it was generating downforce!!!! At 55 MPH it generated so much downforce

that Bob couldn't hold it up anymore. It was then decided that that was sufficient downforce.

The original prototype chassis (without the body). You can see airshocks were used, this was because they didn't have the proper

coil over shocks at this point. This is still the shop at Callins Road. You can see a farm field here looking east from the shop.

This is the parking lot where the driving tests were done for the original protype chassis. Bob had his kids sitting on his lap

steering it while he controlled the throttle. They were "screaming" around the lot doing brodies. The steering worked great from

day one - no changes were ever made to it!

The original prototype chassis (without the body). You can see airshocks were used, this was because they didn't have the proper

coil over shocks at this point. This is still the shop at Callins Road. You can see a farm field here looking east from the shop.

This is the parking lot where the driving tests were done for the original protype chassis. Bob had his kids sitting on his lap

steering it while he controlled the throttle. They were "screaming" around the lot doing brodies. The steering worked great from

day one - no changes were ever made to it!

In the white shirt is Morris Boushay(sp?), one of the original investors. Bob is in the maroon shirt.

In the white shirt is Morris Boushay(sp?), one of the original investors. Bob is in the maroon shirt.

These two people where working on the master for the main body section. The work was not done at the shop (possibly at Fibron

at Compton).

These two people where working on the master for the main body section. The work was not done at the shop (possibly at Fibron

at Compton).

Working on the finished plug for the main body section. You can see the wooden bracing inside so that it holds its proper form.

Working on the finished plug for the main body section. You can see the wooden bracing inside so that it holds its proper form.

The final Plug for the nose section and the engine cover. These are called the master and are the pieces that the actual "Molds"

are taken from.

The final Plug for the nose section and the engine cover. These are called the master and are the pieces that the actual "Molds"

are taken from.

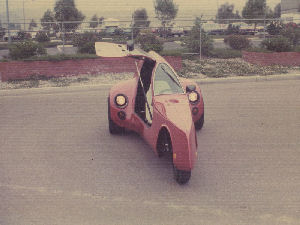

The Ventura County fair in October 1974. This is the prototype vehicle, complete with white shocks and broomhandles holding up

the door!! The strut was installed later.

The Ventura County fair in October 1974. This is the prototype vehicle, complete with white shocks and broomhandles holding up

the door!! The strut was installed later.

Around this time Bob took his car to a car show. He won an outstanding design award trophy for the TriVette that was presented

to him by the world famous automotive designer Alex Tremules!! He was Henry Fords chief designer for decades.

The model inside the car is Bob's wife Diana. This was the first public showing of the TriVette.

The model inside the car is Bob's wife Diana. This was the first public showing of the TriVette.

The prototype in front of 2113 C shop on Palmer drive where the company had moved to. They were running out of room at the old

location and needed to expand. This prototype car is now owned by Bob's brother.

The prototype in front of 2113 C shop on Palmer drive where the company had moved to. They were running out of room at the old

location and needed to expand. This prototype car is now owned by Bob's brother.

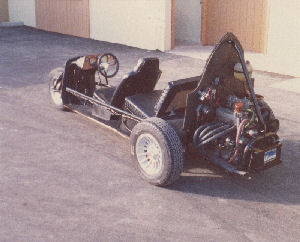

Front 3/4 view of the round tube production frame. The prototype used a square frame and the production cars all used round

tubing. This was taken at 1499 palmer drive, the company needed to move once again to a larger facility to accomadate the larger

production.

Front 3/4 view of the round tube production frame. The prototype used a square frame and the production cars all used round

tubing. This was taken at 1499 palmer drive, the company needed to move once again to a larger facility to accomadate the larger

production.

Rear 3/4 view of the production frame.

Rear 3/4 view of the production frame.

-COMPLETE WITH ROLLBAR-

-- 1975 --

Open Chassis picture of the car for Nishicata - front view.

Open Chassis picture of the car for Nishicata - front view.

A driveable version of the vehicle just needing the body to be complete.

Open Chassis picture of the car for Nishicata - 3/4 rear view.

Open Chassis picture of the car for Nishicata - 3/4 rear view.

Another body-off view of the car - really shows off the parts layout. Notice the cable cluster running along the left rail.

These cables are used for gauges and controls. The cabin heater is under the front seat and the gas tank is under the rear seat!!

The original car didn't have a heater when Bob and Diana took the car for a few day drive that involved going through mountains.

It got so cold in the TriVette on the way over the moutains that Bob designed and installed a heater for the drive back!!! It

worked great and was incorporated in in all production TriVettes.

-- 1976 --

A open-chassis view of the TriVette that was crashed by one of Bob's employees (a younger guy) on Palmer Drive. He was taking the open

chassis TriVette for a test drive to make sure everything was operating properly. He was flying down palmer drive when a guy in a big

6,000 lb ford station wagon pulled out in front of him from one of the local buesnesses. He hit the station wagon right at its

firewall in front of the drivers door. There was 14 feet of skid marks and the estimated impact speed was 45 to 50 MPH. He had no seat

belt on and was brought to the hospital where he only needed a few stitches in his left knee where it hit the dash. He tore a 10"

round circle in his "T" shirt but he was back working the next day. In a typical passenger car that would have been a fatal accident.

Bob told me that typically a passenger car doing 30 MPH into a solid barrior is a fatal accident. The Ford station wagon moved about

6 inches. The TriVettes front suspension, the wheel, and the down tube absorbed the impact progressively giving distance and time

for decelleration. In the picture you can see that the top of the battery is tipped forward and the entire engine is up against the

rear plywood bulkhead. This means that the energy absorbsion went clear to the rear of the vehicle. Again, this is the side view

after the crash.

A open-chassis view of the TriVette that was crashed by one of Bob's employees (a younger guy) on Palmer Drive. He was taking the open

chassis TriVette for a test drive to make sure everything was operating properly. He was flying down palmer drive when a guy in a big

6,000 lb ford station wagon pulled out in front of him from one of the local buesnesses. He hit the station wagon right at its

firewall in front of the drivers door. There was 14 feet of skid marks and the estimated impact speed was 45 to 50 MPH. He had no seat

belt on and was brought to the hospital where he only needed a few stitches in his left knee where it hit the dash. He tore a 10"

round circle in his "T" shirt but he was back working the next day. In a typical passenger car that would have been a fatal accident.

Bob told me that typically a passenger car doing 30 MPH into a solid barrior is a fatal accident. The Ford station wagon moved about

6 inches. The TriVettes front suspension, the wheel, and the down tube absorbed the impact progressively giving distance and time

for decelleration. In the picture you can see that the top of the battery is tipped forward and the entire engine is up against the

rear plywood bulkhead. This means that the energy absorbsion went clear to the rear of the vehicle. Again, this is the side view

after the crash.

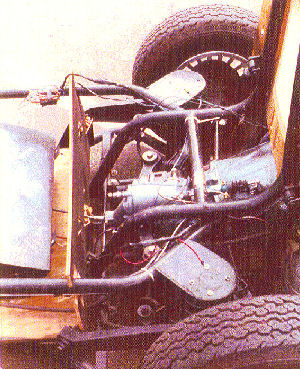

The left side of the engine after the accident with the engine moved well forward.

The left side of the engine after the accident with the engine moved well forward.

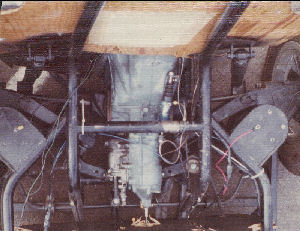

Looking straight down on top of the clutch housing, final drive and transmission. There's a verticle 1-1/2" diameter 095 wall

tube that was about 1/2" in front of the rear axle. The energy stopping the engine and the bending of the engine and transmission

mounts allowed the engine to move forward. You can see where the nose of the transmission shattered the plywood bulkhead that was

right in front of the transmission and also see the bent motor mounts. The thing that stops the engine was the verticle piece of

tubing that's just barely in front of the axle halfshafts. From this picture you can see that the halfshaft is actually bent, this

is a substantial piece of metal. This is what stopped the whole thing from going into the passenger compartment. So this vehicle was

more sucessfull at aborbing impact energy then passenger cars of that day.

Looking straight down on top of the clutch housing, final drive and transmission. There's a verticle 1-1/2" diameter 095 wall

tube that was about 1/2" in front of the rear axle. The energy stopping the engine and the bending of the engine and transmission

mounts allowed the engine to move forward. You can see where the nose of the transmission shattered the plywood bulkhead that was

right in front of the transmission and also see the bent motor mounts. The thing that stops the engine was the verticle piece of

tubing that's just barely in front of the axle halfshafts. From this picture you can see that the halfshaft is actually bent, this

is a substantial piece of metal. This is what stopped the whole thing from going into the passenger compartment. So this vehicle was

more sucessfull at aborbing impact energy then passenger cars of that day.

Side view from the left side again showing how far the motor mount are bent and how the plywood was extreamly effective at absorbing

the impact energy.

Side view from the left side again showing how far the motor mount are bent and how the plywood was extreamly effective at absorbing

the impact energy.

This is Bob in the shop with a foot on a chassis and leaning on another near completion.

This is Bob in the shop with a foot on a chassis and leaning on another near completion.

The fiberglass shop in Compton California - Fiberon. Here they're making the right hand gullwing door. The fiberglass from the

chopper gun setup is being sprayed into the mold to make the new door.

The fiberglass shop in Compton California - Fiberon. Here they're making the right hand gullwing door. The fiberglass from the

chopper gun setup is being sprayed into the mold to make the new door.

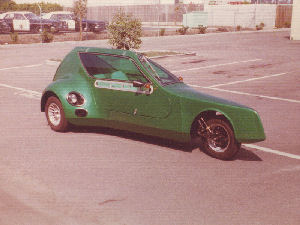

4 Trivettes in front of the shop at 1499 Palmer Drive. The green one was for Paul Stantion in Simi Valley California.

4 Trivettes in front of the shop at 1499 Palmer Drive. The green one was for Paul Stantion in Simi Valley California.

The number one production vehicle in the rear lot. The California Hiway Patrol office is in the background just north of there

production facility. This TriVette is now found at Bob's home in New York.

The number one production vehicle in the rear lot. The California Hiway Patrol office is in the background just north of there

production facility. This TriVette is now found at Bob's home in New York.

This is to show a size comparison between a TriVette and a 1975 chevy pickup. You can see it's allmost as long as a full size

pickup.

This is to show a size comparison between a TriVette and a 1975 chevy pickup. You can see it's allmost as long as a full size

pickup.

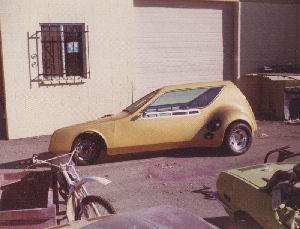

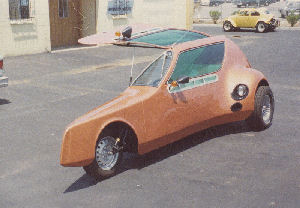

This gold vehicle was delivered to Tepper in El Monte.

This gold vehicle was delivered to Tepper in El Monte.

Same as above but behind the shop.

Same as above but behind the shop.

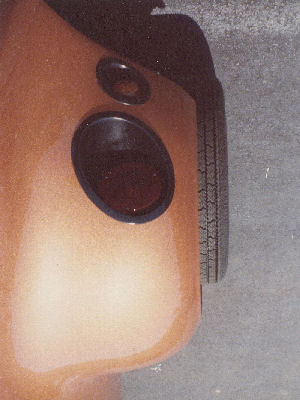

A brown TriVette.

A brown TriVette.

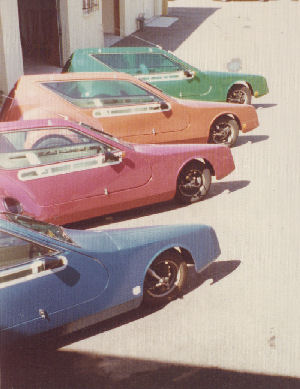

A collection of 4 TriVettes. The green one was Paul Stantions of simi Valley.

A collection of 4 TriVettes. The green one was Paul Stantions of simi Valley.

An enterprising young man from Compton California with his irridescent purple TriVette that he used in his buesness.

An enterprising young man from Compton California with his irridescent purple TriVette that he used in his buesness.

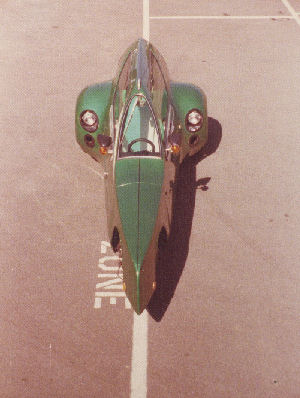

A front overhead view of Paul Stantion's green goldflake TriVette.

A front overhead view of Paul Stantion's green goldflake TriVette.

Another view of Paul's TriVette.

Another view of Paul's TriVette.

Yet another view of Paul's TriVette.

Yet another view of Paul's TriVette.

4 TriVettes in front of the shop there's an appricot, gold, nutmeg, and another apricot. December of 1976.

4 TriVettes in front of the shop there's an appricot, gold, nutmeg, and another apricot. December of 1976.

Another view of the cars - the red one is the #1 production car.

Another view of the cars - the red one is the #1 production car.

May 1976

May 1976

Cars lined up in front of 1499 Palmer - December 1976.

Cars lined up in front of 1499 Palmer - December 1976.

-- 1977 --

Diana showing off the TriVette in front of the Los Angeles Coluseum. Photo was taken by a professional photographer for

a press function.

Diana showing off the TriVette in front of the Los Angeles Coluseum. Photo was taken by a professional photographer for

a press function.

The appricot colored TriVette belonging to Pattersons. This vehicle was one of two that was made race prepped with a 1600 CC dual

port Volkswagon motor complete with a turbo charger!!

The appricot colored TriVette belonging to Pattersons. This vehicle was one of two that was made race prepped with a 1600 CC dual

port Volkswagon motor complete with a turbo charger!!

Interior of Phifer's TriVette. He was from Detriot, Michigan. He also bought a second vehicle but this one was with a turbo

charged Volkswagon motor. There were only two TriVettes built with the Volkswagon engines.

Interior of Phifer's TriVette. He was from Detriot, Michigan. He also bought a second vehicle but this one was with a turbo

charged Volkswagon motor. There were only two TriVettes built with the Volkswagon engines.

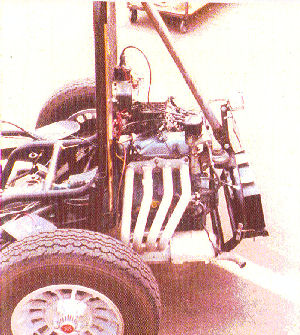

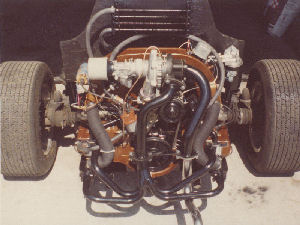

A view of the engine compartment with the turbocharged Volkswagon engine. You can see the turbo on top and how the 4 exhaust

pipe come together in one larger diameter pipe that comes up into the turbine section of the turbo. The output of the turbine, to its

right, is the pipe that forms the exhaust. Because the turbo blades spin at such high RPMs, they chop up the high pressure pulses

comming out of the exhaust ports. So there was no need to have a muffler on the vehicle. On the left side of it you can see the side

draft carburetor comming into the compressor section of the turbocharger. Bob thinks it was a Bendix unit originally intended for

aircraft and motorcycle applications. It delivered an estimated 220 Horse Power from this setup in a vehicle that weighed 1,140 lbs.

The bike comming off the line was ferosious. This vehicle would run the quarter mile in 10.4 seconds at 140 MPH but actually spent the

last couple hundred feet of the quarter mile just sitting there on the red limiter. It would have gone faster with different gearing but

stock Volkwagon gearing was used in this vehicle. This was a VERY fast TriVette.

A view of the engine compartment with the turbocharged Volkswagon engine. You can see the turbo on top and how the 4 exhaust

pipe come together in one larger diameter pipe that comes up into the turbine section of the turbo. The output of the turbine, to its

right, is the pipe that forms the exhaust. Because the turbo blades spin at such high RPMs, they chop up the high pressure pulses

comming out of the exhaust ports. So there was no need to have a muffler on the vehicle. On the left side of it you can see the side

draft carburetor comming into the compressor section of the turbocharger. Bob thinks it was a Bendix unit originally intended for

aircraft and motorcycle applications. It delivered an estimated 220 Horse Power from this setup in a vehicle that weighed 1,140 lbs.

The bike comming off the line was ferosious. This vehicle would run the quarter mile in 10.4 seconds at 140 MPH but actually spent the

last couple hundred feet of the quarter mile just sitting there on the red limiter. It would have gone faster with different gearing but

stock Volkwagon gearing was used in this vehicle. This was a VERY fast TriVette.

Mr. Patterson from Hawaii picking up his TriVette. His biggest problem was trying to decide on the color of his vehicle. He could pick

blue, the same color as the other one in Hawaii, that way if he got caught doing anything he could blame it on the other guy. Or, for

ego, he could pick his own unique color. Ego won out and he chose an appricot color.

Mr. Patterson from Hawaii picking up his TriVette. His biggest problem was trying to decide on the color of his vehicle. He could pick

blue, the same color as the other one in Hawaii, that way if he got caught doing anything he could blame it on the other guy. Or, for

ego, he could pick his own unique color. Ego won out and he chose an appricot color.

The other TriVette in Hawaii was blue and had a special engine, it was a racing Fiat setup will a Paul Baker and Son special

cast aluminum cross well head. The intake was a pair of 40 DCO E Weber side draft carburetors. Bob remembers driving the car to Long

Beach to put it in a container to ship to Hawaii and on a special long straight stretch of the highway that was a 3 lanes wide concrete

section it was showing 135 MPH on the speedometer. "It was FAST for a 903 CC motor!"

Another of Patterson's turbocharged Volkswagon setup.

Another of Patterson's turbocharged Volkswagon setup.

The front left hand fender view of Patterson's vehicle.

The front left hand fender view of Patterson's vehicle.

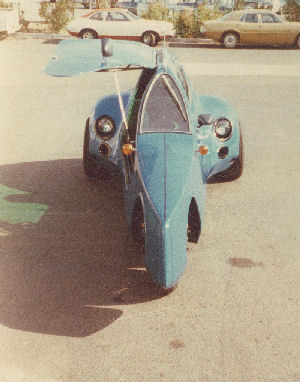

Front right hand view of Patterson's vehicle.

Front right hand view of Patterson's vehicle.

June 1977 - Vehicle originally sent to Teckfor, a machinist in El Monte.

June 1977 - Vehicle originally sent to Teckfor, a machinist in El Monte.

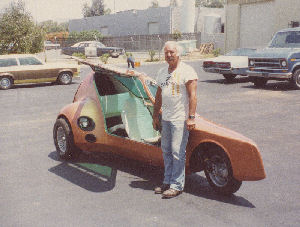

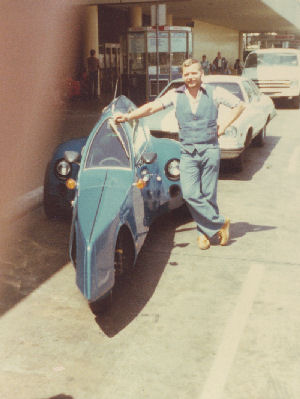

Teckfor standing by his vehicle in front of 1499 Palmer.

Teckfor standing by his vehicle in front of 1499 Palmer.

Teckfor's wife next to the vehicle.

Teckfor's wife next to the vehicle.

-- 1978 --

The blue Volkswagon turbocharged vehicle for phifer from Detroit Michigan.

The blue Volkswagon turbocharged vehicle for phifer from Detroit Michigan.

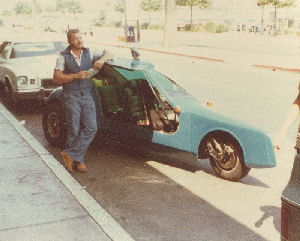

Here is Pfifer's TriVette that Bob drove to the LA Airport. He flew in, took delivery at the airport, and drove it home to Detroit! That

must have been one great ride!

Here is Pfifer's TriVette that Bob drove to the LA Airport. He flew in, took delivery at the airport, and drove it home to Detroit! That

must have been one great ride!

Another photo of Pfifer at the airport.

Another photo of Pfifer at the airport.

Yet another picture of Pfifer's TriVette.

Yet another picture of Pfifer's TriVette.

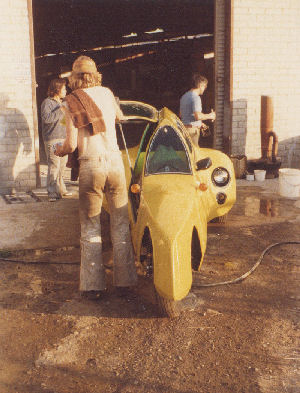

The banana yellow TriVette. The fellow with his back to us is Carl Bob's son. It's being finished up at Vincent Pora's place in Santa Pala.

Had allready moved things from 1499 Palmer.

The banana yellow TriVette. The fellow with his back to us is Carl Bob's son. It's being finished up at Vincent Pora's place in Santa Pala.

Had allready moved things from 1499 Palmer.

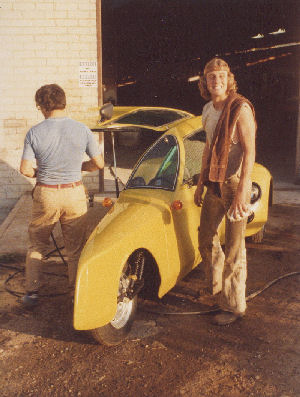

Vincent Pora can be seen on the left with his back to the camera and Carl on the right side.

Vincent Pora can be seen on the left with his back to the camera and Carl on the right side.

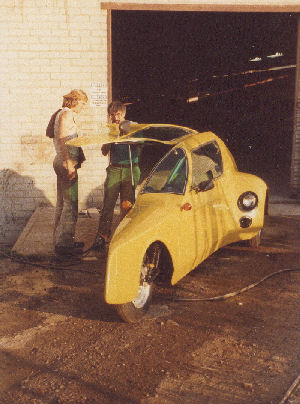

One more as above.

One more as above.

One more as above.

One more as above.

One more as above.

One more as above.

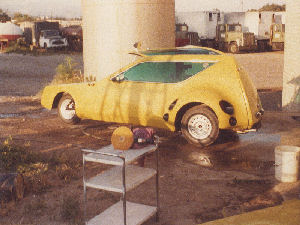

Another at Vincent pora's place which was a truck repair place.

Another at Vincent pora's place which was a truck repair place.